- Printing Graphic Arts

- Brand

- Interface

- Model

- Product

- 550 Icolor Printer (4)

- Blade (2)

- Carriage Pca Board (2)

- Cutter (5)

- Engraver (2)

- Fiber Laser Engraver (2)

- Graphichs (3)

- Ink Reservoir (2)

- Photo Printer (2)

- Plotter (173)

- Print Head (4)

- Printer (3)

- Printer Stand (3)

- Roland Main Board (2)

- Vinyl Cutter (199)

- Vinyl Cutter Plotter (3)

- Water Chiller (2)

- Wide Format Printer (2)

- ... (5216)

- Type

- Clamshell Heat Press (26)

- Cutting (229)

- Dye Sublimation (18)

- Eco-solvent (53)

- Embosser Machine (12)

- Engraving Machine (199)

- Equipment (15)

- Flash Dryer (11)

- Flatbed (22)

- Guillotine Cutter (9)

- Heat Press (12)

- Heat Press Machine (30)

- Ink Pad (19)

- Inkjet (226)

- Large Format Press (10)

- Large Format Printer (14)

- Laser (27)

- Latex (32)

- Paper Cutter (36)

- Sublimation Press (144)

- ... (4487)

- Working Voltage

19.3 4908 Paper Cutter Knife Guillotine, Touch Screen, High Production US Stock

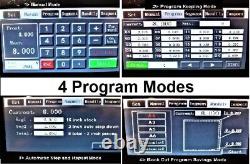

Electric Paper Cutter with Touch Screen Program. Program Modes: Manual Entry, Program Cut Saving, Automatic step and repeat, Book system cut saved. Complete sensor check, Adjustable Clamping Hold Time before the knife cuts, Adjustable Cutting Depth when setting a new blade, Adjustable Hand Wheel fast and slow speed for running the back gauge, Switching from English Standard to Metric. How a paper cutter works.

You program the length you want to cut on a keyboard or touch screen, 2', 5.5" 10" etc. Next pushing a go button the back plate or what is called a (back gauge) moves to the programed location for the cut, 2', 5.5" 10" etc. It is called a back gauge because it gauges the distance of where the back plate stops behind the blade. The paper size needed is cut behind the blade between the back gauge and the blade. You push your paper stack up against the back stop plate (back gauge) and square it up.

You push the 2 cut buttons and a clamp comes down and holds the paper and a blade follows cutting the paper. Next you go to the next cut and do the same again if another cut is needed.1- Does it keep the cuts square and the same exact width from one end of the sheet to the other? Example: cutting a 2" strip must be 2" across the whole sheet and need to be exact or as close as possible. Not 2 wide on one sheet end and 2 1/16 wide on the other end. The back gauge and the blade needs to be exactly parallel with each other.

Most cutters require constant adjustment of the back stop plate or (back gauge) to keep it parallel with the blade. This is because of the design and the back gauge being attached or mounted to a small block in the center of the cutter bed. This block is driven by a threaded rod under the cutter bed.

Elite cutters with the solid plate back gauge design. This back plate or back gauge design stays square with a wide stabilizer plate. This plate keeps the back gauge square and parallel with the blade. This design has the back gauge mounted and driven from above the cutter bed allowing for a much stronger support attaching the back gauge to a wide plate that is set square to the blade.

See attached photos of the above back gauge mounting. Does it keep the paper from cutting on an angle from the top of the stack to the bottom of the stack. Example: cutting a 2" strip with week clamping pressure will cut 2" wide at the top of the stack and 2 1/32 at the bottom of the stack from the paper pulling over while cutting. As the blade gets dull the angle gets worse.

Many cuts are done by following a cut line and most copiers do not register perfectly to start with. Adding a cut variance only creates a larger problem.The cutter requires a strong clamping pressure holding the paper down while the blade cuts through it to avoid the paper from pulling over from top of the s tack to the bottom of the stack and cutting the stack on an angle - this is called (paper draw) in the cutting industry. A Strong Clamping Motor: 720 psi upgrade motor design from the 380 psi original import motor.

Authorized sales and service trained distributor. Toll free number for support.

Touch Pad Programmer, 1-99 channel saving programs. Automatic with cut or just Clamping before you cut. Table Length In Front of Knife. Crate Weight and Cutter Weight.Crate 42" x 34" x 33 Machine 37x 29.5x 48.5. 110V 60hz standard or 220V 50hz request. Specifications Subject to Change without Notice.

You will receive access to our toll free number for any help needed by our Professional staff as well as our you tube videos on blade changing, lubricating, and some parts replacements, which will help you get the maximum value from your investment. We do not sell any machines coming out of China that we have not inspected ourselves as being safe and reliable. Problems we have seen: (blades that cycle without pushing buttons, safety systems that stop working when a sensor goes out not related to the safety system, blades that stop and then cycle again while reaching for the cut stock, machines not properly grounded that shock you) we have seen it all and most manufacturers do not correct the problem. If visual damage is noticed to the package or container (please do not accept it without inspecting the contents first). If inspection is not allowed do not accept the item or you may end up having to keep a damaged item and risk loosing your rights for recovery.Not all items allow a return unless not as described or damaged and the package or container does not show any outer damage. Policy to follow if receiving a damaged item (keep the evidence). Policy to follow if returning an item.

Your satisfaction is our first priority. We will take care of the cost to send the replacement item to you.

If agreed upon we may pay for return because of other reasons. We do everything in our power to explain all we can about the product being represented. We sell no reproductions or copies unless explained and then we will normally sell as new. We insure and require signature for the buyers protection. They are taking away their ability to inspect an item for acceptance if damaged and wave any claims.

It is at the buyers own risk of loss by forfeiting the rights for a claim if this happens. We package and deliver to the courier service being used for confirmation of receiving the item and weight. If any of the below questions are yes please let us know. Additional options which are added cost will be sent through a. Larger items like crated or skidded items sometimes require additional cost.Sea port or inland port with term of CFR as default , Not to your address. It is optional term of DDU to your door. (The only arrival port in UK is Felixstowe) (The only arrival port in Canada is Vancouver). The default Chinese dispatch port is Huangpu port in Guangzhou, there is only one schedule each week, closed each Tue and barge leaves each Fri. But does not leave every day.

Possible delay is subject to accident factors like overstock, schedule change, strike, bad weather, holidays etc. It is a VERY important and necessary document, we will send you this form for file prior to dispatch. Those are not included in your prepayment. We view our customers as business partners and future income, please follow policies as we will do everything to maintain our relationship with the same respect.

Our experts are well versed in the products provided and have the knowledge to help you identify product potential and/or worth. This item is in the category "Business & Industrial\Printing & Graphic Arts\Bindery & Finishing Equipment\Paper Cutters & Trimmers". The seller is "fitzantiquities" and is located in this country: US. This item can be shipped to United States.- Material: Paper

- Operation Type: Electric

- Type: Paper Cutter

- Brand: Unbranded