- Printing Graphic Arts

- Brand

- Expiration Date

- Material

- Abs+ Aluminium Alloy (11)

- Acrylic (5)

- Acrylic & Aluminum (15)

- Aluminium (4)

- Aluminum (144)

- Aluminum Alloy (7)

- Aluminum Frame (5)

- Ceramic (3)

- Glass (4)

- Iron (3)

- Mechanical Steel (4)

- Metal (428)

- Metal, Aluminum (4)

- Paper (133)

- Plastic (29)

- Polyester (7)

- Polymeric Pretreated (8)

- Steel (81)

- Vinyl (22)

- Wood (7)

- ... (4668)

- Model

- Product

- 550 Icolor Printer (3)

- Blade (2)

- Carriage Pca Board (2)

- Cutter (5)

- Engraver (2)

- Fiber Laser Engraver (2)

- Graphichs (3)

- Ink Reservoir (2)

- Photo Printer (2)

- Plotter (162)

- Print Head (4)

- Printer (3)

- Printer Stand (3)

- Roland Main Board (2)

- Vinyl Cutter (195)

- Vinyl Cutter Plotter (3)

- Water Chiller (2)

- Wide Format Printer (2)

- ... (5193)

- Type

- Clamshell Heat Press (26)

- Cutting (224)

- Dye Sublimation (18)

- Eco-solvent (53)

- Embosser Machine (12)

- Engraving Machine (199)

- Equipment (15)

- Flash Dryer (11)

- Flatbed (19)

- Guillotine Cutter (9)

- Heat Press (12)

- Heat Press Machine (30)

- Ink Pad (19)

- Inkjet (215)

- Large Format Press (10)

- Large Format Printer (14)

- Laser (26)

- Latex (32)

- Paper Cutter (36)

- Sublimation Press (144)

- ... (4468)

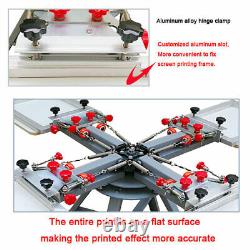

Manual 6 Color 6 Station Micro Registration tshirt Screen Printing Press Machine

US Stock, 6 Color 6 Station. Silk Screen Printing Press Machine.

The Manual of the Screen Printing Machine in PDF. The machine is 6 color 6 station screen printing machine. Suitable for one or two people to use. Users just need to stand in one platen station to work, platen station and. Frame can rotate in 360 degree.

To station location, it don't need the operator move to work. Mainly used for T-shirt printing, also printed cloth and other products. Optional flash dryer, and the dryer place in the upside of printing station's platen, drying the surface of material after printing for 3-5 seconds, then printing the next color, improve the work efficiency, two people operate(one people printing, one people place the T-shirt and drying platen, Fold the printed T-shirts)Printed.Four-color T shirt 200-250 pieces per hour. Platen size: 17.7" x 21.6"(55 x 45cm). Max frame size: 20" x 24" (50 x 60 cm). Max image size: 15.7"x 20"(40 x 50 cm).

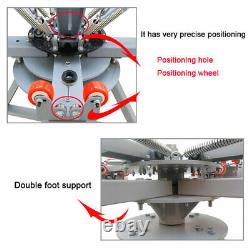

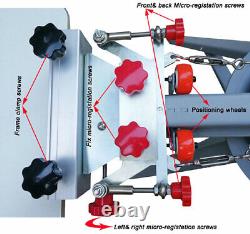

Both shirtboard layer and screen layer can rotate independently. Smart micro registration device for printing multicolor precisely. Screens can be adjusted front, back, lefe right through micro microregistration.

Aluminium screen clamps can be adjusted up and down horizontally, beautiful and pratical. All heads can be pressed down at same time, can print multicolor on multiple stations.

Special design of spring device adjust tension for screen up and down. Double fix position device is an initiate design, makes color registration accurate. Detachable bracket facilitates interchange shirtboards.

Bigger and thicker steel round plate, more stable when printing. Add the triangle support under pallet plate, 35mm diameter bigger axis. Heavy gauge all steel construction, electroplating coating, durable, no rust. Stands can be adjusted up and down, and be detachable for packing. Equipped with a full set of installation and maintenance tools and spare parts.

Composite structure for packing and transportation. Gross weight: 341 lb(155 kg). Packing size: in 1 wooden case. 43.3 x 26.8 x 19.7 inch(110 x 68 x 50 cm).